Exploring the Production Process of Membrane Switch for Numerous Industries

The manufacturing process of Membrane buttons is a complex undertaking that requires precision and interest to information. From picking ideal products to carrying out strenuous quality assurance steps, each step plays a crucial role in ensuring functionality. Numerous sectors, consisting of clinical and automotive, depend on these components for their special applications. Comprehending the intricacies of this procedure reveals considerable understandings right into just how these switches are generated and their influence across varied industries.

Understanding Membrane Switches Over: A Review

Trick Products Used in Membrane Switch Manufacturing

In Membrane button production, the selection of vital materials greatly affects functionality and longevity. Conductive products, adhesives, and finishings play crucial roles, while substrate option influences total performance and reliability. Recognizing these elements is vital for optimizing the design and production of Membrane buttons.

Conductive Materials Overview

Conductive materials play a vital function in the performance of Membrane switches, making certain reliable electric links within the gadget. Typically utilized materials include silver, copper, and carbon-based inks, each offering distinct benefits. Silver is favored for its high conductivity and durability, making it ideal for applications requiring robust efficiency. Copper, while slightly much less conductive than silver, is an affordable option typically utilized in published circuits. Carbon-based inks provide a versatile option, suitable for applications where versatility and reduced costs are prioritized, although they have actually reduced conductivity contrasted to steel alternatives. The option of conductive materials directly impacts the total reliability, life-span, and performance of the Membrane button, making it an important factor to consider in the production procedure.

Adhesives and Coatings

Adhesives and coverings are necessary components in the production of Membrane switches, giving vital bonding and protective homes. These materials assure that different layers of the button, consisting of graphic overlays and wiring, stick securely to each other, enhancing resilience and capability. Commonly used adhesives consist of pressure-sensitive adhesives (PSAs) and epoxy-based formulations, which provide strong adhesion and resilience. Coatings, such as polyurethane or acrylic, offer to secure against environmental variables, consisting of dampness, abrasion, and chemicals. Furthermore, finishings can enhance responsive responses and aesthetic appeal, adding to the general customer experience. The choice of appropriate adhesives and coatings is essential for optimizing performance and durability in diverse applications throughout various sectors, making sure that Membrane switches satisfy particular operational demands.

Substrate Selection Aspects

Substrate selection plays an essential duty in the manufacturing of Membrane switches, as it significantly influences their total performance and longevity. Trick products such as polyester, polycarbonate, and adaptable published circuit card (FPCBs) are commonly used for their distinct properties. Polyester is favored for its cost-effectiveness and resistance to abrasion, making it ideal for applications with high wear. Polycarbonate deals exceptional quality and impact resistance, perfect for settings calling for high exposure. FPCBs give improved adaptability and are usually made use of in complicated designs. The selection of substrate also impacts factors like thermal stability, chemical resistance, and convenience of printing. Eventually, picking the appropriate substratum is critical for making certain the functionality and long life of Membrane switches across various industries.

The Layout Process of Membrane Switches Over

The design process of Membrane switches is a crucial stage that significantly affects the performance and aesthetics of the end product - membrane switch manufacturer. It begins with specifying the specific demands of the application, consisting of measurements, button layout, and responsive responses preferences. Designers need to take into consideration user interaction, making sure that the button is user-friendly and accessible.Next, materials are chosen based upon resilience, flexibility, and environmental resistance. The combination of graphics and branding components is additionally essential, as it boosts visual appeal and communication. Prototyping allows for repetitive testing, allowing changes based on customer responses and efficiency evaluations.Additionally, the style has to represent the electrical elements, such as circuits and adapters, making certain integrity and ease of usage. Eventually, a successful design harmonizes capability, looks, and customer experience, paving the way for efficient production and durable performance in numerous markets

Printing Strategies for Membrane Switches Over

The printing techniques made use of in Membrane button manufacturing play an essential function in figuring out the last product's quality and functionality. Display printing uses advantages such as resilience and lively color application, while electronic printing developments provide versatility and precision in style. Comprehending these techniques can significantly impact the overall efficiency of Membrane buttons in numerous applications.

Display Printing Advantages

Various benefits make display printing a preferred method for creating Membrane buttons. This method permits premium, comprehensive styles and vibrant shades, which are crucial for interface applications. Screen printing is especially reliable for using thick ink layers, enhancing resilience and responsive responses. Additionally, it provides exceptional adhesion to various substratums, making certain longevity sought after settings. The process is cost-effective for huge manufacturing runs, as it decreases configuration time and waste. Moreover, display printing sustains a wide variety of inks, consisting of specialized and UV-curable alternatives, enabling versatility in style. Its capability to create constant results across several systems makes it a trusted option for makers aiming for high quality and efficiency in Membrane button manufacturing.

Digital Printing Innovations

Advancements in electronic printing modern technology are changing the production of Membrane switches, supplying makers innovative solutions that improve layout versatility and efficiency. Digital printing enables intricate layouts and high-resolution graphics, allowing customized branding and capability without the constraints of conventional approaches. This technique minimizes setup times and costs, assisting in shorter manufacturing runs and minimal waste, making it suitable for businesses with differing demands. Additionally, innovations in ink solutions provide much better longevity and adhesion, making sure long life in various atmospheres. As sectors increasingly seek tailored and complicated layouts, electronic printing attracts attention as an important technique, setting a new standard in Membrane button manufacturing. The assimilation of these developments settings makers to meet progressing market requires successfully.

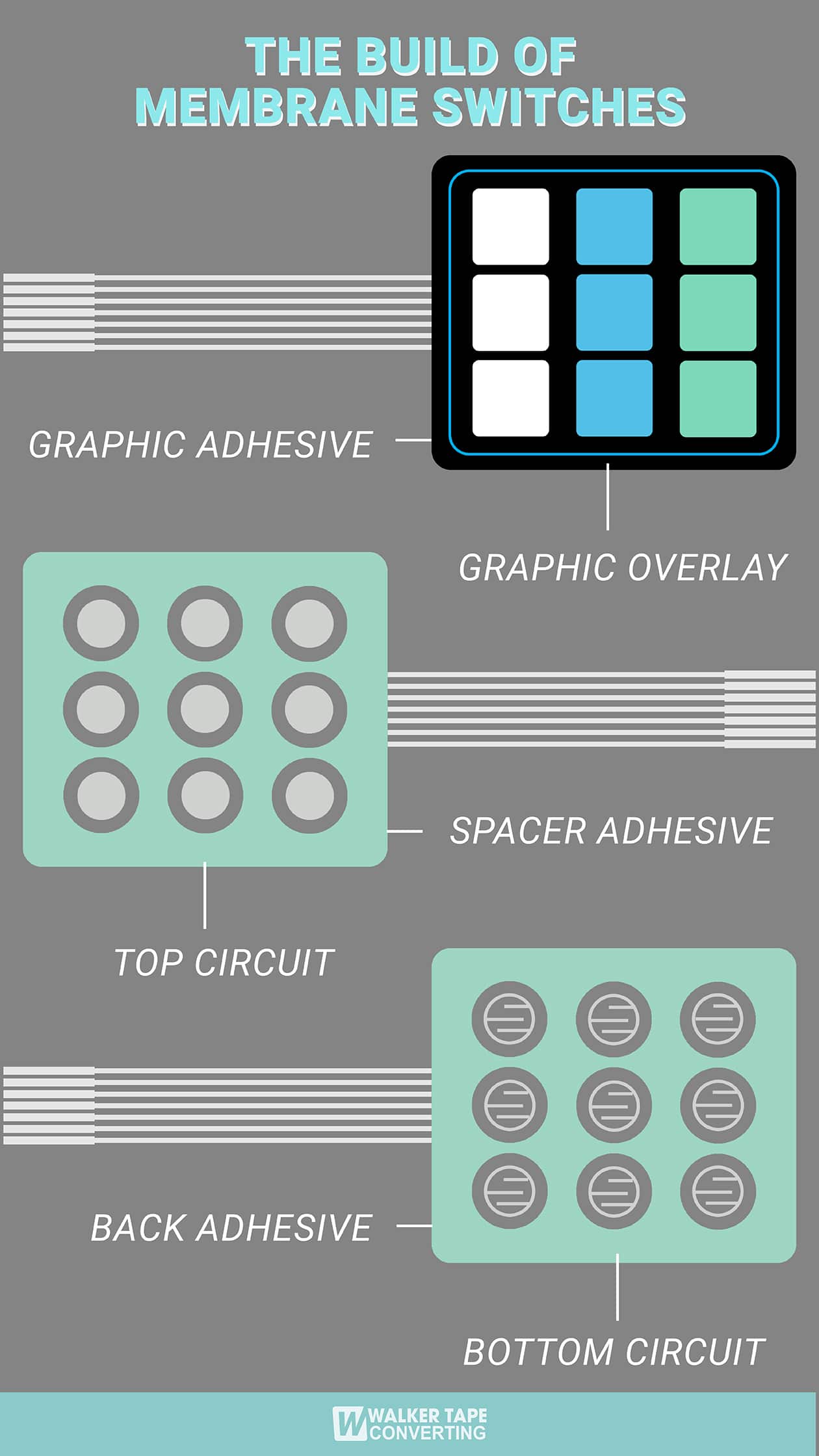

Assembly and Layering of Membrane Switch Parts

Cautious setting up and layering of Membrane switch components are important to assuring functionality and longevity. This process starts with the accurate positioning of numerous layers, including the visuals overlay, glue, circuit layer, and support product. Each part has to be carefully placed to maintain electrical stability and user interface responsiveness.During assembly, conductive traces are related to the circuit layer, normally made from products like polyester or polycarbonate. This layer is crucial, as it beams when stress is used. The adhesive utilized for bonding these layers is also chosen for its capacity to sustain ecological tensions while preserving a safe and secure bond.Heat and pressure are typically used throughout the setting up process to identify that the layers adhere appropriately without endangering the functionality of the switch. Interest is offered to the side securing to safeguard versus moisture and pollutants, protecting the durability of the Membrane switch in numerous industrial applications.

Quality Assurance Procedures in Membrane Switch Production

Quality assurance actions play a necessary duty in guaranteeing the integrity and performance of Membrane switches over following the setting up and layering of their elements. In the production process, numerous essential inspections are conducted to promote high quality requirements. These include visual assessments for issues in printing and glue application, in addition to useful tests to verify the responsiveness of each switch.Additionally, environmental screening is performed to evaluate the buttons' sturdiness versus temperature fluctuations and moisture direct exposure. Manufacturers typically apply statistical process control (copyright) strategies to keep an eye on manufacturing consistency, enabling early detection of anomalies.Furthermore, traceability systems are established to track materials and components, guaranteeing accountability and promoting recalls if essential. Calibration of tools and adherence to market criteria are likewise essential to maintaining item honesty. Collectively, these quality control steps safeguard the performance of Membrane switches throughout different applications, ultimately enhancing client contentment.

Applications of Membrane Switches Over Across Different Industries

Membrane buttons are utilized throughout a diverse selection of industries, showcasing their versatility and adaptability. In the medical market, they give dependable and water resistant user interfaces for gadgets such as analysis tools and mixture pumps, making certain health and ease of usage. The vehicle market utilizes Membrane buttons for control panel controls, allowing smooth interaction between the motorist and automobile helpful site systems.In consumer electronics, these switches are located in appliances and portable gadgets, providing a streamlined, modern-day aesthetic while improving functionality. Industrial applications also utilize Membrane switches for machinery control panels, where toughness and resistance to rough conditions are essential.Furthermore, the aerospace and protection fields make use of Membrane buttons for cabin instrumentation and interaction systems, focusing on dependability and efficiency under severe conditions. In general, Membrane buttons play a crucial duty in boosting the user experience and functional effectiveness throughout numerous domains.

Frequently Asked Concerns

The length of time Does It Require To Produce a Membrane Switch?

The production time for a membrane button commonly varies from a few days to a number of weeks - membrane switch manufacturer. Aspects influencing this period include style intricacy, material availability, and manufacturing volume, all impacting the total timeline markedly

What Is the Regular Lifespan of a Membrane Layer Switch?

The common life expectancy of a membrane layer button typically varies from 1 to 5 million actuations, depending upon aspects such as material quality, environmental conditions, and usage regularity, greatly impacting sturdiness and overall performance.

Can Membrane Changes Be Customized for Details Applications?

Membrane switches can certainly be personalized for certain applications. Their layout adaptability permits changes in dimension, form, shades, and graphics, guaranteeing compatibility with unique requirements throughout numerous markets and boosting performance and user experience.

Are Membrane Switches Eco-friendly?

The environmental This Site effect of Membrane switches over differs. Some products utilized might not be eco-friendly, while improvements in producing procedures are progressively concentrating on sustainability, aiming to lower waste and advertise recyclable parts in their production.

What Are the Common Failing Modes of Membrane Switches?

Common failing modes of Membrane buttons consist of delamination, adhesive failure, wear and tear from usage, wetness ingress, and electric failings. These problems can substantially impact capability, efficiency, and life-span in various applications across various sectors. Membrane switches can be personalized to fit specific layout needs, such as form, dimension, and performance, making them very adaptable.The building commonly entails several layers, consisting of a visuals overlay, glue, and a circuit layer, which function with each other to produce a smooth user experience. In Membrane button manufacturing, the option of essential materials considerably affects functionality and durability. The auto sector uses Membrane switches for control panel controls, making it possible for smooth interaction in between the motorist and automobile systems.In customer electronics, these switches are discovered in devices and portable devices, supplying a sleek, modern-day aesthetic while enhancing functionality. Industrial applications additionally utilize Membrane switches for equipment control panels, where sturdiness and resistance to rough problems are essential.Furthermore, the aerospace and protection sectors utilize Membrane buttons for cabin instrumentation and interaction systems, focusing on dependability and efficiency under extreme conditions. Membrane buttons can certainly see this page be customized for particular applications.